The new technique has proven to be three times more efficient than the current one and also promotes the growth of blood vessels within it

The bones are the scaffolding in our bodies. Bone fractures are long to treat and kilurgically complex injuries. In the case of complex damage, chyurgists use powders or pastes to replace the damaged tissue in the bone. New research proposes an innovative method that improves on previous techniques. The study was conducted between Oregon Health & Science University, the University of Oregon, New York University and Mahidol University in Thailand. The results were published in the journal Advanced Materials.

You might also be interested in -> 3D “printed” ankle: record-breaking intervention in Bologna

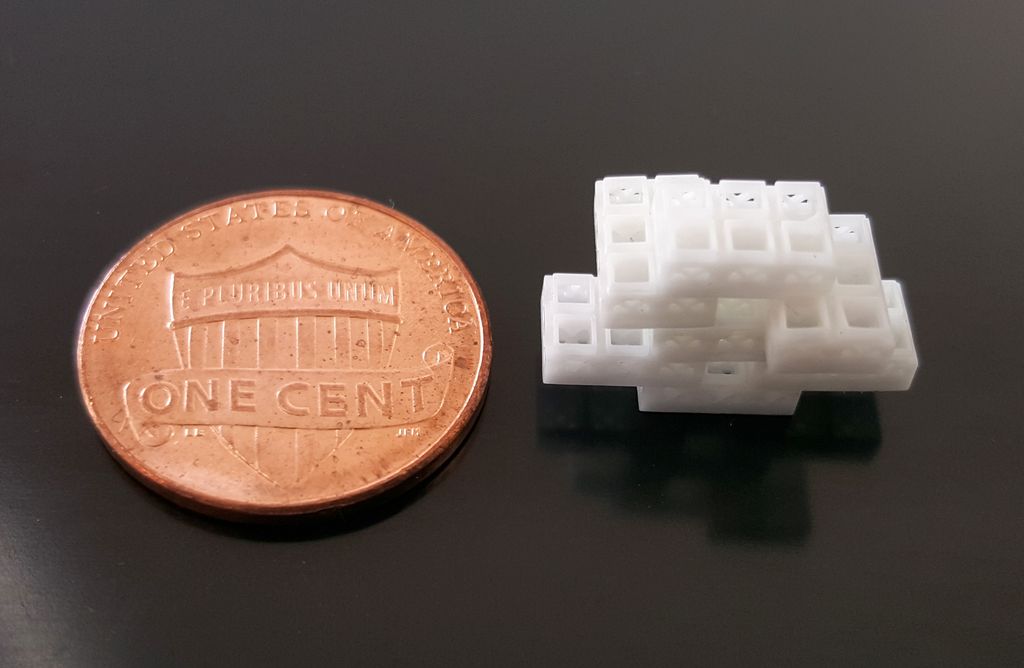

The researchers produced a structure consisting of small cubes with sides of only 1.5 mm. The mini cubes are able to retain gels with growth factors, promoting the formation of new cells. The tissue deposits on the scaffolding of the cubes and replaces the damage caused by the injury. Early tests on mice have shown that the mini cubes promote blood vessel production with three times the effectiveness of other techniques. In addition to the soft tissue, the hard tissue also benefits from the scaffolding by incorporating it during growth.

You might also be interested in -> Italian surgeons implanted the first ear “built” thanks to 3D printing

The invention is waiting to be patented. The great advantage of the cubic structure is that it can be modified at will and can be adapted to the shape and size of many situations. Flexibility in production is provided by the 3D printing method, which makes the process easy to apply and spread. The next steps will see the mini cubes used on lesions in biggest animals and, finally, in humans. The ultimate goal is the development of large organs and tissues printed completely in 3D.