The new yarn product is made from two renewable marine resources and is a promising material for advanced applications in textiles and medicine

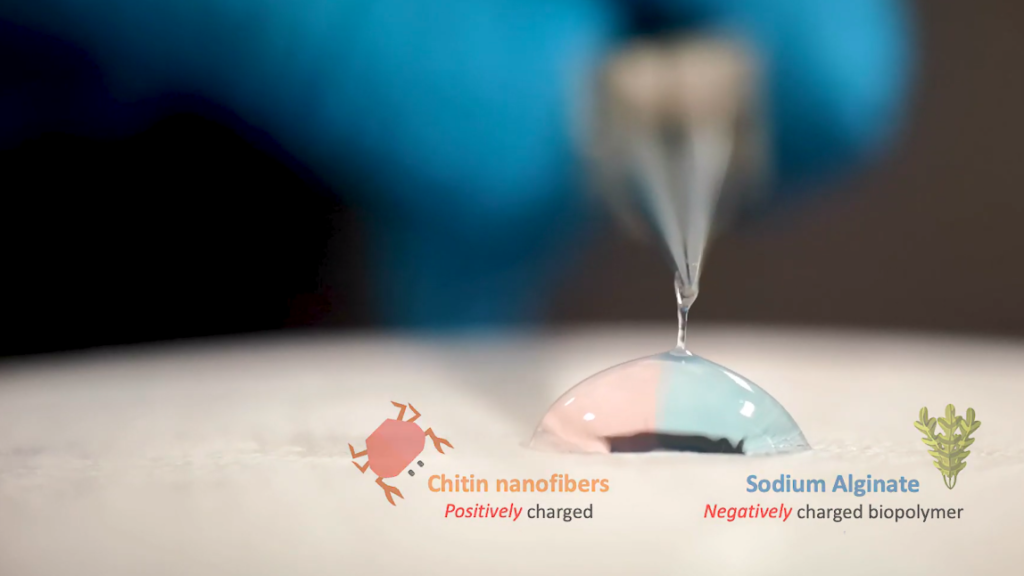

The ecological impact on the way we work and do research is also entering the field of yarn and fashion. Researchers from the University of Aalto, the University of Sao Paulo and the University of British Columbia have made their contribution by creating a new sustainable, robust and antimicrobial fiber. The starting materials are derived from sustainable resources, chitin present in the crab shell residues and alginate present in seaweed.

The combination of the two polysaccharides in the form of nanoparticles produces a material that maintains the two original properties of the basic components, the strength of chitin and the flexibility of alginate. The results of the study have been published in the journal ACS Sustainable Chemistry & Engineering and report how changes in concentrations, nanoparticle size or other parameters affect the properties of the algae.

The fibers form on the contact surface of the two solutions, with the alginate enveloping the chitin nanoparticles, producing microfibers that are arranged in parallel during spinning. The (laboratory) spinning process is very similar to nylon production. The strong interaction in the fibrils is guaranteed by the opposite charge of algiline and chitin.

Researchers think that their fiber has great potential as a chyrurgical material for sutures or as tapes for inner tissues. Further uses could include skin netting and swabs, wound care or burn treatment, since chitin is antimicrobial. The next step will be the development of a production method for large quantities. Researchers have already shown that it is possible to produce threads on a continuous basis, now it will be necessary to move from the laboratory scale to much larger production volumes.