COBAT and CNR have filed a patent for an innovative technology that will enable the recycling of lithium-ion batteries in electric cars at sustainable costs.

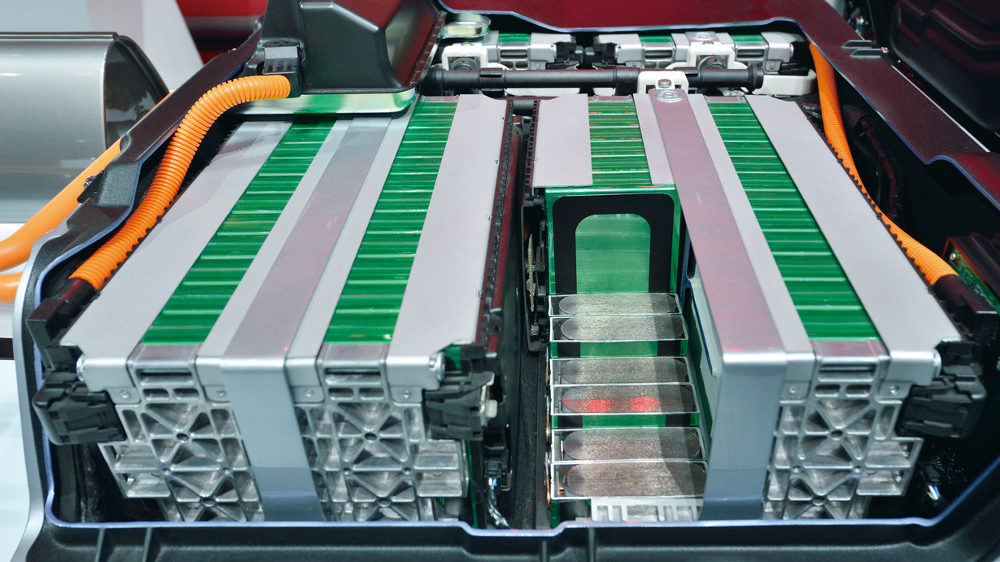

The car of the future will be electric. There are few doubts about this: sales data and market analyses confirm that the four-wheeler world is definitely focusing on electricity, a greener and more sustainable source of energy compared to “traditional” hydrocarbons. On a numerical level, the world electric automotive market is growing strongly and the main stakeholders in the sector are investing large sums of money in the development of electric-powered models. Research is also making important steps forward and, in Italy, a patent has just been filed, which could mark an epoch-making turning point. It is a technology that allows the recycling at sustainable costs of metals (cobalt, nickel, manganese and especially lithium) present in batteries that supply energy to electric cars. The treatment of these substances is one of the obstacles that most hinder the spread of electric cars in the world. Currently there is no efficient system to treat and dispose of electric car batteries safely. Once removed from vehicles, the batteries of electric cars – very different from those of traditional cars, for which there is a very precise disposal procedure – are shipped to Germany and literally “burned” in special industrial plants. What remains, the so-called “black mass” is shipped to China or South East Asia and then disposed of. This is a very long chain that involves very high operating costs.

A patent for the recovery of electric car batteries

The patent was created thanks to the collaboration between the Italian Consortium for the collection and recycling of spent batteries and accumulators (COBAT), Cnr-Iccom of Florence and Cnr-Itia of Milan, under the coordination of the Politecnico di Milano. The patent is based on a hydrometallurgical process, i.e. the use of acid solutions to recover the minerals present in batteries. “In Europe there is no one who has developed this type of technology”, explains Cobat’s research and study manager Luigi De Rocchi, “Italy could therefore play an important role in a circular economy”. The treatment with acid substances, in fact, maximizes the recovery of lithium and allows to give new life to spent batteries. “On average, the useful life of a lithium battery used in electric cars is about eight years, after which they begin to lose their driving force. But by reusing them for storage, they can double their life.