Researchers in San Diego have developed an ultrasonic device that applied to lithium metal batteries increases their life, charge and capacity

The development of batteries is a very lively field, whose importance was recognized by the award of the Nobel Prize in Chemistry in 2019. The most widespread are Lithium ion batteries, which are excellent for the high number of charging cycles they can withstand. Lithium metal batteries have a higher charge density but are not suitable for recharging. The obstacle is the formation of metal accumulations in the electrolyte liquid, called dendrites.

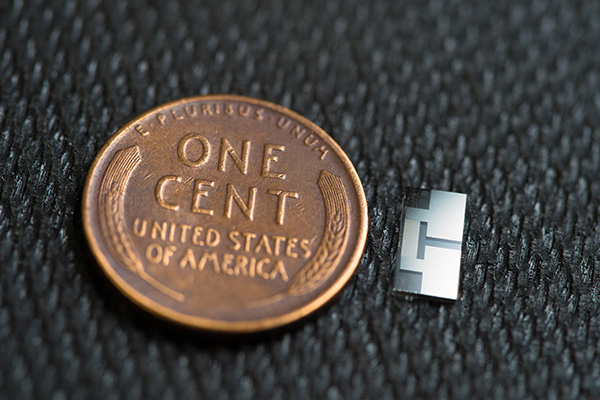

A group of researchers, led by James Friend, developed a device that emits ultrasound to complement the batteries. The waves emitted generate a movement in the battery liquid between the anode and cathode. The continuous movement of the electrolyte prevents the formation of dendrites, Lithium metal agglomerates. The device is an integral part of the battery but can also be used in other types of batteries, regardless of type.

The sound waves generated are very high frequency, between 100 million and 10 billion Herz. These frequencies are used in smartphone to filter the wireless signal and improve the quality of the audio output. Lithium metal batteries equipped with the device can be charged and discharged up to 250 times and lithium ion batteries up to more than 2000 times. Charging times are also improved, as the batteries are recharged from zero to 100% in 10 minutes.

The study was conducted at the University of California at San Diego and details were published in the journal Advanced Materials. The device could pave the way for the commercialization of lithium metal batteries as an alternative to the current ones. The main advantage respect to the Lithium ion batteries is the power doubled at equal weight. Among all, the most interested fields are certainly electric cars, where weight reduction is the main obstacle to the production of effective and performing vehicles.