The new design, proposed by a company in the Czech Republic, makes it possible to build 3D printed houses drastically reducing time and halving production costs

The evolution of 3D printing is rapidly accelerating, finding application in several fields. These include construction. 3D printing of housing structures has already existed for many years and is carried out by means of large robotic arms. The houses built by Prvok od Burinky represent a conceptual innovation that could have a great impact on the environment.

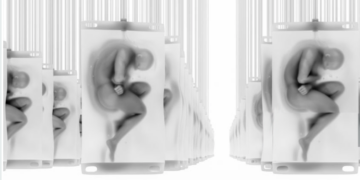

The modules have three rooms and an area of 43 square meters and are built with a special concrete containing polypropylene nanofibers. The walls are moulded to form a double layer which will be filled with insulating material. The structure can be printed in 24-48 hours and takes about 28 days to solidify completely.

The applications are unlimited, from private home to commercial or tourist use. One idea is to make houses on floating docks to increase the building area in cities such as Belgrade, Hamburg and Canadian cities. The process and asymmetric design will reduce carbon dioxide emissions by 20% compared to equivalent brick construction. In addition, it will use less polluting material in construction and produce less waste during demolition.